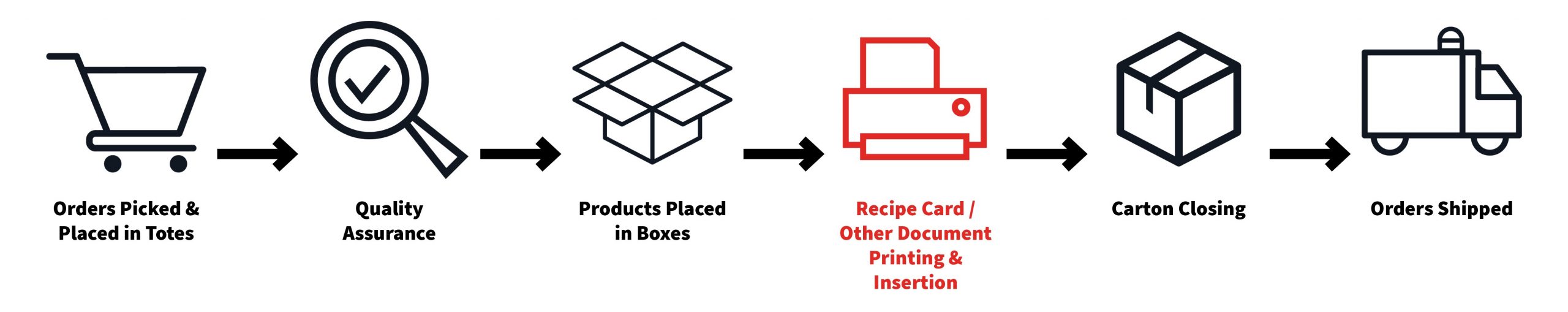

An Online Grocery Company was struggling to keep up with the exponential growth it experienced over the past few years. Realizing that the majority of errors occurred at the document insertion station, they worked with a Consultant to optimize their processes in the new fulfillment centers. PSI designed and installed a document insertion conveyor line using Print Feeders to automate this problematic transaction area.

THE SITUATION

A rapidly growing grocery delivery company was working with a Consultant to open several fulfillment centers across the country that were designed to optimize to fulfill customer orders in the fastest, most cost-efficient way. The Company was committed to delivering fresh, locally sourced produce to their customer base at a reasonable price, so they were looking for ways to ensure orders were processed quickly and with minimal errors to keep their operating costs low.

Included in every order was a thank you card, a referral card (with a personalized promo code for each customer), and a flyer advertising upcoming promotions and new products. These inserts varied in size from 6.42”x7.58” to 8.5”x14”. For new customers only, a welcome brochure was included with their first order.

At existing facilities, document printing and insertion was completed manually by a team of up to 10 operators whose jobs consisted in picking the appropriate documents from the stacks of pre-printed materials, printing the personalized promo codes on the referral card, and inserting the correct documents into the customer’s order. This manual process resulted in a high error rate because the wrong code often got sent to the wrong customer or the wrong advertisement was inserted. Since the amount of material required varied each month (depending on order volume and marketing campaigns in place), there was always too much or not enough of the pre-printed material available.

THE RECOMMENDATION

Three Print Feeders were installed in-line to print the full-color, cardstock document insertions (one document type per Print Feeder). As the carton passed by on the conveyor, the barcode was scanned and each Print Feeder printed the appropriate promotional flyer, referral card with personalized promo code, and personalized thank you card and inserted it into the order. One LC In-Feeder was installed downstream of the Print Feeders to feed the welcome brochure into orders for new customers.

THE RESULTS

Using the Print Feeders to automate document printing and insertion, this customer saved over $500,000 on labor costs alone. The Print Feeders installed took up less space than the station they had initially planned for with manual operators. Automation had also decreased the number of errors in document insertion to zero.