Automated Pack Stations 101

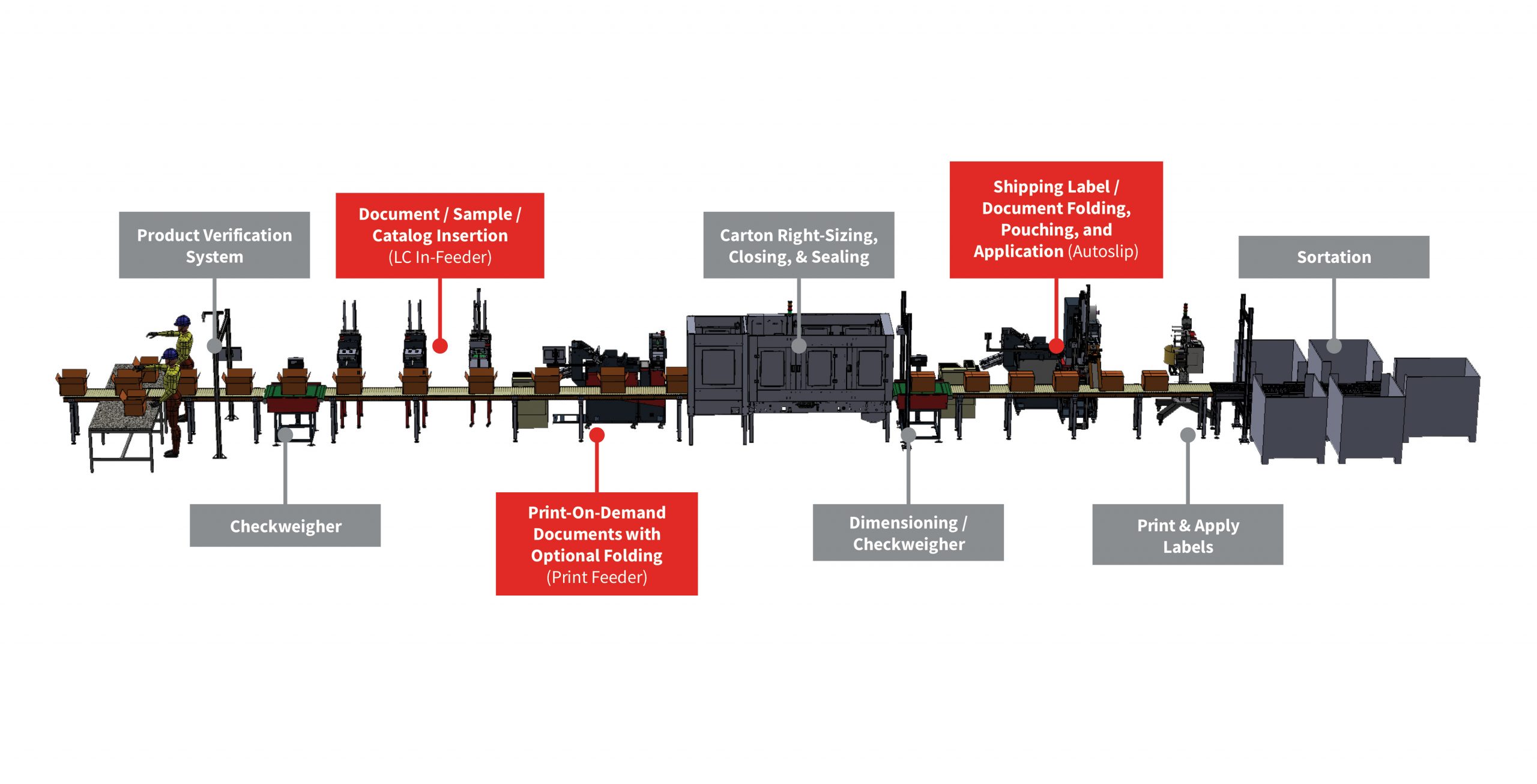

The warehouse pack station is where inventory is capitalized by converting inventory to orders in the space between the pick area and the shipping/staging dock(s). By automating repetitive manual tasks, this is done more efficiently and more rapidly. Introducing automation into the pack station can increase throughput to up to 900-1,200 packages per hour (depending on how much is automated and the size of packages).

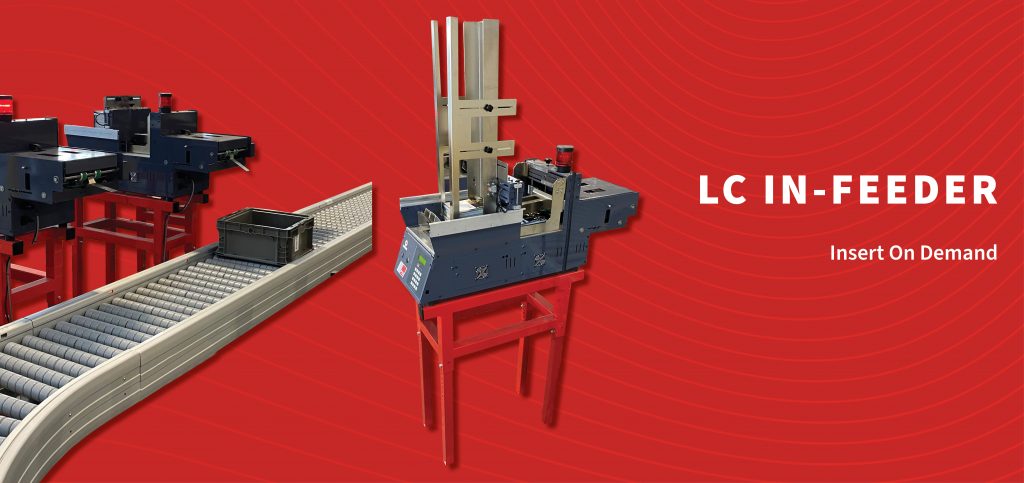

Document/Sample/

Catalog Insertion

The LC In Feeder automates material or pre-printed document insertion in the pack line. PSI’s large capacity friction feeder offers packaging solutions for high volumes of media, such as catalogs, to be fed from the inline dispensing system into boxes or totes along the conveyor line.

Print-On-Demand Documents with Optional Folding

Print Feeders print documents, from packing slips to greeting cards, on demand and folds either once or twice before feeding them into passing totes, cartons, or boxes. The resulting increased packing station efficiency allows for faster order fulfillment and a higher throughput.

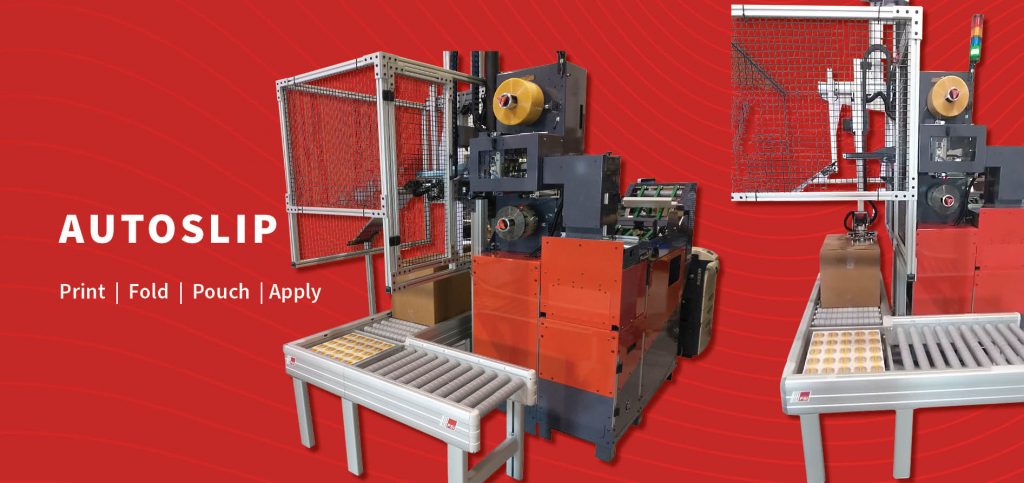

Shipping Label/Document Folding, Pouching, and Application

The Autoslip can handle printing, folding, and inserting documents (packing slips, return labels, etc.) of up to 10 pages all in one step. Automating document printing, folding, and insertion increases packing station throughput, without adding more stations and reduces labor costs associated with fulfillment.

Click the link below to learn more about Peripheral Products / Other Pack Station Components

Click the link below to learn more about Conveyance and Sortation Systems

Why work with PSI for your Automated Pack Station Needs

We specialize in the last 100 feet of the order fulfillment line to help high volume distribution centres optimize throughput and accuracy while reducing labor costs. PSI Engineering is the technology leader in the manufacture and integration of automated pack and sortation systems, print-on-demand systems, and print-and-apply systems for even the most complex high volume warehouse and distribution environments.

We design, build and integrate fully configured pack station and order fulfillment automation solutions. Our systems ensure increased throughput and accuracy, greater reliability and seamless operation, while reducing labor costs.

Ideally though we provide seamless cradle to grave solutions for clients looking to improve efficient and costs by automating their PackStation area. When clients want to relieve congestion or bottlenecking in the pack station or have the need to reimplement FTEs in their operation is where we provide the greatest value. Let us work with you to provide a fully Automated Pack Station leaving you to focus on the rest of your distribution warehouse needs.

We can also provide similar solutions on the induction side of a warehouse by helping with the IB sort or by doing order start if that is an option for our client and their WMS.

Based on your specific needs, we can customize a pack station using any or all of the parts above. In addition, we can accommodate automation of steps including:

- Carton Erectors

- Packing slip/return label printing and inserting into an adhesive pouch

- Reject lines/Hospital lanes

- Sortation based on parcel destination (check out or Conveyance and Sortation page for more information)